PORTWELL PCI-DIO-24D

Description

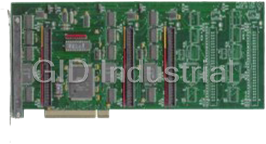

24-bit parallel, digital input/output cards designed for use in PCI-Bus computers. The difference between the models is that I/O connections to PCI-DIO24D are via a standard 37-pin D-sub connector while I/O connections to PCI-DIO24H are via a 50-pin connector. The half length universal cards are 4.80 inches long (122 mm) and may be installed in any 3.3/5V PCI-bus slot in IBM and compatible personal computers.

Part Number

PCI-DIO-24D

Price

Request Quote

Manufacturer

PORTWELL

Lead Time

Request Quote

Category

PCI Digital I/O Products

Specifications

Categorization Information

PCI Digital IO Products

Features

- Universal PCI, PCI-X, 3.3V and 5V compatible

- 24 bits of digital I/O] {Four and eight bit ports independently selectable for I/O

- All 24 I/O lines buffered by transceivers on the card

- I/O buffers can be enabled/disabled under program control

- Pull-ups on I/O lines

- Resettable fused +5 VDC output available

- 'H' version compatible with industry-standard I/O racks from Western Reserve Controls, Gordos, OPTO22, Potter & Brumfield, etc.

- Optional 1 MHZ counters

- Automatically detected under Windows 95/98/NT/XP

- No base address or IRQ switches to set

- RoHS compliant versions available

Datasheet

Extracted Text

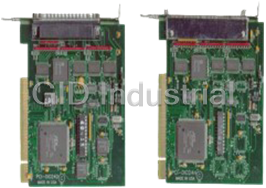

MODEL PCI-DIO-24D(H) USER MANUAL FILE: MPCI-DIO-24DH.G1o Notice The information in this document is provided for reference only. Portwell does not assume any liability arising out of the application or use of the information or products described herein. This document may contain or reference information and products protected by copyrights or patents and does not convey any license under the patent rights of Portwell, nor the rights of others. IBM PC, PC/XT, and PC/AT are registered trademarks of the International Business Machines Corporation. Printed in USA. Copyright 2001, 2005 by Portwell I/O Products Inc. All rights reserved. WARNING!! ALWAYS CONNECT AND DISCONNECT YOUR FIELD CABLING WITH THE COMPUTER POWER OFF. ALWAYS TURN COMPUTER POWER OFF BEFORE INSTALLING A CARD. CONNECTING AND DISCONNECTING CABLES, OR INSTALLING CARDS INTO A SYSTEM WITH THE COMPUTER OR FIELD POWER ON MAY CAUSE DAMAGE TO THE I/O CARD AND WILL VOID ALL WARRANTIES, IMPLIED OR EXPRESSED. Manual PCI-DIO-24DH 2 Warranty Prior to shipment, Portwell equipment is thoroughly inspected and tested to applicable specifications. However, should equipment failure occur, Portwell assures its customers that prompt service and support will be available. All equipment originally manufactured by Portwell which is found to be defective will be repaired or replaced subject to the following considerations. Terms and Conditions If a unit is suspected of failure, contact Portwell' Customer Service department. Be prepared to give the unit model number, serial number, and a description of the failure symptom(s). We may suggest some simple tests to confirm the failure. We will assign a Return Material Authorization (RMA) number which must appear on the outer label of the return package. All units/components should be properly packed for handling and returned with freight prepaid to the Portwell designated Service Center, and will be returned to the customer's/user's site freight prepaid and invoiced. Coverage First Three Years: Returned unit/part will be repaired and/or replaced at Portwell option with no charge for labor or parts not excluded by warranty. Warranty commences with equipment shipment. Following Years: Throughout your equipment's lifetime, Portwell stands ready to provide on-site or in-plant service at reasonable rates similar to those of other manufacturers in the industry. Equipment Not Manufactured by Portwell Equipment provided but not manufactured by Portwell is warranted and will be repaired according to the terms and conditions of the respective equipment manufacturer's warranty. General Under this Warranty, liability of Portwell is limited to replacing, repairing or issuing credit (at Portwell discretion) for any products which are proved to be defective during the warranty period. In no case is Portwell liable for consequential or special damage arriving from use or misuse of our product. The customer is responsible for all charges caused by modifications or additions to Portwell equipment not approved in writing by Portwell or, if in Portwell opinion the equipment has been subjected to abnormal use. "Abnormal use" for purposes of this warranty is defined as any use to which the equipment is exposed other than that use specified or intended as evidenced by purchase or sales representation. Other than the above, no other warranty, expressed or implied, shall apply to any and all such equipment furnished or sold by Portwell. Manual PCI-DIO-24DH 3 Table of Contents Chapter 1: Introduction................................................................................................. 5 Specifications ............................................................................................................ 7 Figure 1-1: Card D or H Block Diagram .................................................................. 8 Chapter 2: Installation................................................................................................. 10 Chapter 3: Option Selection ....................................................................................... 12 Figure 3-1: Option Selection Map version D.......................................................... 13 Figure 3-2: Option Selection Map version H ......................................................... 13 Chapter 4: Address Selection .................................................................................... 14 Chapter 5: Software .................................................................................................... 15 Chapter 6: Programming ............................................................................................ 16 Table 6-1: Address Assignment Table................................................................... 16 Table 6-2: Control Register Bit Assignment........................................................... 17 Chapter 7: 8254 Counter/Timer .................................................................................. 21 Chapter 8: Connector Pin Assignments.................................................................... 27 Table 8-1: 50-Pin Connector Pin Assignments...................................................... 27 Table 8-2: 37-Pin D-Sub Connector Pin Assignments........................................... 28 Manual PCI-DIO-24DH 4 Chapter 1: Introduction Features • 24 Bits of Digital Input/Output. • All 24 I/O Lines Buffered on the Card. • I/O Buffers Can Be Tri-stated under Program Control. • Four and Eight Bit Ports Independently Selectable for I/O. • Pull-Ups on I/O Lines. Pull Down resistors may be installed at the factory (**per port 8 bit**) • Resettable fused +5V Supply Available to the User. • "H" version compatible with Industry Standard I/O Racks. • Three optional i8254 type (**9 16-bit converters**) counters. Applications • Automatic Test Systems. • Laboratory Automation. • Robotics. • Machine Control. • Security Systems, Energy Management. • Relay Monitoring and Control. • Parallel Data Transfer to PC. • Sensing Switch Closures or TTL, DTL, CMOS Logic. • Driving Indicator Lights or Recorders. Description The card comes in two basic models. The difference between the two models is that I/O connections to the D are via a standard 37-pin D-sub connector while I/O connections to the H are via a 50-pin connector. The cards are 4.8 inches long and may be installed in any 5V PCI-bus slot in IBM and compatible personal computers. These cards provide 24 bits of parallel digital input/output on the PCI bus. These cards contain a type 8255-5 Programmable Peripheral Interface (PPI) chip. They can be programmed to accept inputs or to provide outputs on three 8-bit ports designated Ports A, B, and C. Port C can be further divided into two 4-bit nibbles. The direction of each port is independent of other ports. Also, bit 3 of Port C can be used as an internal interrupt to the computer if the Interrupt Select 0 jumper is installed in the INT position. On the card, the EXT interrupt position is for factory testing. When bit C3 goes low (edge triggering) an interrupt is requested. Each I/O line is buffered by a type 74ABT245B tristate buffer transceiver capable of sourcing 32 mA or sinking 64mA. Pull-ups on the card assure that there are no erroneous outputs at power up until the card is initialized by system software. The buffers are configured automatically by hardware logic for input or Manual PCI-DIO-24DH 5 output use according to direction assignment from a control register in the PPI. Further, if a jumper is properly placed on the card, the tristate buffers may be enabled/disabled under program control. (See the Option Selection section to follow.) I/O wiring connections for the H card are via a 50-pin connector on the back plate of the card. Flat insulation-displacement ribbon cables can be used to connect these cards to termination panels and relay output cards. Also, the 50-pin connection provides compatibility with OPTO-22, Gordos, Potter & Brumfield and Western Reserve Controls module mounting racks. Fused +5 VDC power is available on the I/O connector at pin 49. The on-board fuse is rated at 0.5A at room temperature, and can be reset by cycling computer power, or by removing the load. I/O wiring connections for the D card are via a 37-pin D-sub connector on the back plate of the card. A 37-pin D-sub solder cup mating connector, or flat insulation-displacement ribbon cable can be used to connect these cards to termination panels. The "D" version has a fused 5 volts available at connector pin 20. The on-board fuse is rated at 0.5A, and can be reset the same as the H version. Manual PCI-DIO-24DH 6 Specifications Digital Inputs (TTL Compatible) • Logic High: 2.0 to 5.0 VDC • Logic Low: -0.5 to +0.8 VDC • Load: ±20 μA Digital Outputs • Logic High: 2.0 VDC min., source 32 ma • Logic Low: 0.55 VDC max., sink 64 ma Optional Counter/Timers • Type: 82C54 programmable interval counters (up to three) • Output drive: Source 2.5 mA, sink 24 mA • Input Gate: TTL/CMOS compatible • Clock: On-board, 1 MHz crystal-controlled oscillator • Active Count Edge: Negative edge (falling edge) • Minimum Clock Pulse Width: 30 ns high, 40 ns low • Timer Range: 16 bits (x3 per i8254) • Power Output: Resettable 0.5A fused +5 VDC from computer bus Power Required • Basic Unit: +5 VDC at 170 mA typical if no current is drawn from the auxiliary fused +5 VDC output • With One Counter: +5 VDC at 190 ma • With Two Counters: +5 VDC at 210 ma • With Three Counters: +5 VDC at 230 ma Environmental • Operating Temperature Range: 0 °C. to 60 °C • Storage Temperature Range: -50 °C. to +120 °C • Humidity: 0 to 90% RH, non-condensing • Size: 4.8" Long (122 mm) Manual PCI-DIO-24DH 7 Figure 1-1: Card D or H Block Diagram Manual PCI-DIO-24DH 8 Optional Counter/Timers These cards have options to include one, two, or three 82C54 counter(s) that each include three 16-bit counter/timers factory configured in an optimal module for use as event counters, frequency output, pulse width, and frequency measurement. See the Block Diagram which shows one 82C54 counter. If your card has one or more of these optional counters, an -S01, -S02, or -S03 is appended to the model number for one, two, or three counters respectively. For example, a 24-bit digital input/output card with a 50-pin connector and two 82C54 counters is model H-S02. Note If you have a model D-S03, then the fused +5V power output is not available. Manual PCI-DIO-24DH 9 Chapter 2: Installation A printed Quick-Start Guide (QSG) is packed with the card for your convenience. If you’ve already performed the steps from the QSG, you may find this chapter to be redundant and may skip forward to begin developing your application. The software provided with this card is on CD and must be installed onto your hard disk prior to use. To do this, perform the following steps as appropriate for your operating system. Configure Card Options via Jumper Selection Before installing the card into your computer, carefully read Chapter 3: Option Selection of this manual, then configure the card according to your requirements. Our Windows based setup program can be used in conjunction with Chapter 3 to assist in configuring jumpers on the card, as well as provide additional descriptions for usage of the various card options. CD Software Installation The following instructions assume the CD-ROM drive is drive “D”. Please substitute the appropriate drive letter for your system as necessary. DOS 1. Place the CD into your CD-ROM drive. 2. Type B - to change the active drive to the CD-ROM drive. 3. Type GLQR?JJ- to run the install program. 4. Follow the on-screen prompts to install the software for this board. WINDOWS 1. Place the CD into your CD-ROM drive. 2. The system should automatically run the install program. If the install program does not run promptly, click START | RUN and type B GLQR?JJ, click OK or press -. 3. Follow the on-screen prompts to install the software for this board. LINUX 1. Please refer to linux.htm on the CD-ROM for information on installing under linux. Caution! * ESD A single static discharge can damage your card and cause premature failure! Please follow all reasonable precautions to prevent a static discharge such as grounding yourself by touching any grounded surface prior to touching the card. Manual PCI-DIO-24DH 10 Hardware Installation 1. Make sure to set switches and jumpers from either the Option Selection section of this manual or from the suggestions of SETUP.EXE. 2. Do not install card into the computer until the software has been fully installed. 3. Turn OFF computer power AND unplug AC power from the system. 4. Remove the computer cover. 5. Carefully install the card in an available 5V or 3.3V PCI expansion slot (you may need to remove a backplate first). 6. Inspect for proper fit of the card and tighten screws. Make sure that the card mounting bracket is properly screwed into place and that there is a positive chassis ground. 7. Install an I/O cable onto the card’s bracket mounted connector. 8. Replace the computer cover and turn ON the computer which should auto-detect the card (depending on the operating system) and automatically finish installing the drivers. 9. Run PCIfind.exe to complete installing the card into the registry (for Windows only) and to determine the assigned resources. 10. Run one of the provided sample programs that was copied to the newly created card directory (from the CD) to test and validate your installation. The base address assigned by BIOS or the operating system can change each time new hardware is installed into or removed from the computer. Please recheck PCIFind or Device Manager if the hardware configuration is changed. Software you write can automatically determine the base address of the card using a variety of methods depending on the operating system. In DOS, the PCI\SOURCE directory shows the BIOS calls used to determine the address and IRQ assigned to installed PCI devices. In Windows, the Windows sample programs demonstrate querying the registry entries (created by PCIFind and NTIOPCI.SYS during boot-up) to determine this same information. Manual PCI-DIO-24DH 11 Chapter 3: Option Selection Refer to the setup programs on the CD provided with the card. Also, refer to the Block Diagram and the Option Selection Map when reading this section of the manual. Buffer Mode Jumper A means of enabling or disabling (tristating) the 74ABT245B input/output buffers under program control is provided at the jumper position labeled TST/BEN. When the jumper is in the BEN (Buffer Enable) position, the I/O buffers are always enabled. When the jumper is in the TST (Tristate) position, enabled/disabled state is controlled by a control register. See Chapter 6, Programming for a description. Note A jumper must be installed in EITHER the TST or the BEN position for the card to function. Interrupt Mode Jumpers Place the Interrupt Select 0 jumper in the INT position to select the Digital I/O interrupt. Place the Interrupt Select 0 jumper in the EXT position to select the External Input interrupt. Install the IRQD jumper to enable the Digital I/O or External Input interrupts. Install the IRQT jumper to enable the Timer generated interrupt. The foregoing are the only manual setups necessary to use these cards. Input/Output selection is done via software by writing to a control register in the PPI as described in the Programming chapter of this manual. Optionally, the card may have been modified at the factory to convert the pull up resistors to pull down resistors. The model number would then be similar to D S04 or H S04. Manual PCI-DIO-24DH 12 4.8" IRQD IRQT TST INTEN BEN INT EXT INTSEL0 Figure 3-1: Option Selection Map version D Figure 3-2: Option Selection Map version H Manual PCI-DIO-24DH 13 3.9" Chapter 4: Address Selection These cards use one address space and occupy sixteen I/O locations. The S03 (which has 3 counters) version takes up 32 I/O locations. PCI architecture is Plug-and-Play. This means that the BIOS or Operating System determines the resources assigned to PCI cards rather than the user selecting those resources with switches or jumpers. As a result, you cannot set or change the card's base address or IRQ level. You can only determine what the system has assigned. To determine the base address that has been assigned, run the PCIFind.EXE utility program provided. This utility will display a list of all of the cards detected on the PCI bus, the addresses assigned to each function on each of the cards, and the respective IRQs (if any) allotted. Alternatively, some operating systems (Windows95/98/2000) can be queried to determine which resources were assigned. In these operating systems, you can use either PCINT or the Device Manager utility from the System Properties Applet of the control panel. These cards are installed in the Data Acquisition class of the Device Manager list. To display a list of the resources allocated, select the card, click "Properties", and then select the "Resources Tab". PCIFind uses the Vendor ID and the Device ID to search for your card, then reads the base address and IRQ assigned. If you want to determine the base address and IRQ assigned, use the following information. The Vendor ID for these cards is 494F. The device ID's are: D version: 0C51 H version: 0C50 D w/Counters: 0E52 H w/Counters: 0E51 The PCI bus supports 64K of address space, your card's addresses may be located anywhere in the 0000 to FFFF hex range. Manual PCI-DIO-24DH 14 Chapter 5: Software There are sample programs provided with the card in C, Pascal, QuickBASIC, and several Windows languages. DOS samples are located in the DOS directory and Windows samples are located in the WIN32 directory. The following paragraphs describe the setup program and the 16- and 32-bit utility drivers. SETUP.EXE This program is supplied in the root or base directory as a tool for you to use in configuring jumpers on the card. It is menu-driven and provides pictures of the card on the computer monitor. You make simple keystrokes to select functions. The picture on the monitor then changes to show how the jumper should be placed to effect your choices. The setup program is a stand-alone program that can be run at any time. It does not require that the card be plugged into the computer for any part of the setup. The program is self-explanatory with operation instructions and on-line help. To run this program, at the DOS prompt, enter SETUP.EXE followed by -. Manual PCI-DIO-24DH 15 Chapter 6: Programming These cards are I/O-mapped devices that are easily configured from any language and any language can easily perform digital I/O through the card's ports. This is especially true if the form of the data is byte or word wide. All references to the I/O ports would be in absolute port addressing. Developing Your Application Software If you wish to gain a better understanding of the programs on diskette, then the information in the following paragraphs will be of interest to you. Refer to the data sheets and 8255-5 specification in Appendix A. A total of 16 register locations are used by these cards. With all counters (S03), the total becomes 32 register locations. Address Port Assignment Operation Base Address PA Group 0 Read/Write Base Address +1 PB Group 0 Read/Write Base Address +2 PC Group 0 Read/Write Base Address +3 Control byte Write Only Base Address +4 Unused Base Address +5 Unused Base Address +6 Unused Base Address +7 Unused Base Address +8 Unused Base Address +9 Unused Base Address +C Enable/Disable Buffer Write Only Base Address +D Disable Interrupts Write Only Base Address +E Enable Interrupts Write Only Base Address +F Clear Interrupt latch Write Only Base Address +10 Counter/Timer A0 Read/Write Base Address +11 Counter/Timer A1 Read/Write Base Address +12 Counter/Timer A2 Read/Write Base Address +13 Counter/Timer A Control Read/Write Base Address +14 Counter/Timer B0 Read/Write Base Address +15 Counter/Timer B1 Read/Write Base Address +16 Counter/Timer B2 Read/Write Base Address +17 Counter/Timer B Control Read/Write Base Address +18 Counter/Timer C0 Read/Write Base Address +19 Counter/Timer C1 Read/Write Base Address +1A Counter/Timer C2 Read/Write Base Address +1B Counter/Timer C Control Read/Write Table 6-1: Address Assignment Table Manual PCI-DIO-24DH 16 These cards use an 8255-5 PPI to provide a total of 24 bits input/output capability. The card is designed to use the PPI in Mode 0 wherein: a. There are two 8-bit groups (A and B) and two 4-bit groups (C Hi and C Lo). b. Any port can be configured as an input or an output. c. Outputs are latched. d. Inputs are not latched. The PPI contains a Control Register. This write-only, 8-bit register is used to set the mode and direction of the ports. At Power-Up or Reset, all I/O lines are set as inputs. The PPI should be configured during initialization by writing to the Control Registers even if the ports are only going to be used as inputs. Output buffers are automatically set by hardware according to the Control Register states. Note that Control Register is located at base address +3 and bit assignments are as follows: Bit Assignment Code D0 Port C Lo (C0-C3) 1=Input, 0=Output D1 Port B 1=Input, 0=Output D2 Mode Select 1=Mode 1, 0=Mode 0 D3 Port C Hi (C4-C7) 1=Input, 0=Output D4 Port A 1=Input, 0=Output D5,D6 Mode Select 00=Mode 0, 01=Mode 1, 1X=Mode 2 D7 Mode Set Flag 1=Active Table 6-2: Control Register Bit Assignment Note Mode 1 cannot be used by these cards without modification (Consult factory.). Thus, bits D2, D5, and D6 should always be set to "0". If your card has been modified for use in Mode 1, then there will be an Addenda sheet in the front of this manual. These cards cannot be used in PPI Mode 2 because of byte & nibble wide buffering . Note In Mode 0, do not use the control register byte for the individual bit control feature. The hardware uses the I/O bits to control buffer direction on this card. The control register should only be used for setting up input and output of the ports and enabling the buffer. These cards provide a means to enable/disable the tristate I/O buffers under program control. If the TST/BEN jumper on the card is installed in the BEN position, the I/O buffers are permanently enabled. However, if that jumper is in the TST position, enable/disable of the buffers is software controlled via the control register as follows: a. The card is initialized in the input mode by the computer reset command. b. When bit D7 of the Control Register is set high, direction of the three groups of the associated PPI chip as well as the mode can be set. For example, a write to Base Address +3 with data bit D7 high programs port direction at 0 ports A, B, and C. If, for example, hex 80 is sent to Base Address +3, the Port 0 PPI will be configured in mode 0 with Groups A, B, and C as outputs. At the same time, data bit D7 is also latched in a buffer controller for the associated PPI chip. A high state disables the buffers and, thus, all four buffers will be put in the tristate mode; i.e. disabled. Manual PCI-DIO-24DH 17 c. Now, if any of the ports are to be set as outputs, you may set the values to that port with the outputs still in the tristate condition. (If all ports are to be set as inputs, this step is not necessary.) d. If data bit D7 is low when the control byte is written, ONLY the associated buffer controller is addressed. If, for example, a control byte of hex 80 has been sent as previously described, and the data to be output are correct, and it is now desired to open the three groups, then it is necessary to send a control byte of hex 00 to base address +3 to enable the Port 0 buffers. When you do this, the buffers will be enabled. Note All data bits except D7 must be the same for the two control bytes Those buffers will now remain enabled until another control byte with data bit D7 high is sent to base address +3. Manual PCI-DIO-24DH 18 Programming Example (C) The following program fragment in C language illustrates the foregoing: const BASE_ADDRESS 0x300; outportb(BASE_ADDRESS +3, 0x89); /*This instruction sets the mode to Mode 0, ports A and B as output, and port C as input. Since bit D7 is high, the output buffers are set to tristate condition. See item b. above.*/ outportb(BASE_ADDRESS,0); outportb(BASE_ADDRESS+1,0); /*These instructions set the initial state of ports A and B to all zeroes. Port C is not set because it is configured as an input. See item c. above.*/ outportb(BASE_ADDRESS +3, 0x09); /*Enable the tristate output buffers by using the same control byte used to configure the PPI, but now set bit D7 low. See item d. above.*/ Programming Example (Basic) The following example in BASIC is provided as a guide to assist you in developing your working software. In this example, the card base address is 2D0 hex and the I/O lines of group 0 are to be setup as follows: Port A = Input Port B = Output Port C Hi = Input Port C Lo = Output The first step is to configure the control register. Configure bits of the control register as: D7 1 Active Mode Set D6 0 Mode 0 D5 0 Mode 0 D4 1 Port A = input D3 1 Port C Hi = input D2 0 Mode 0 D1 0 Port B = output D0 0 Port C Lo -= output This corresponds to 98 hex. If the card address is 2D0 hex, use the BASIC OUT command to write to the control register as follows: 10 BASEADDR=&H2D0 20 OUT BASEADDR+3,&H98 To read the inputs at Port A and the upper nybble of Port C: 30 X=INP(BASEADDR)'Read Port A 40 Y=INP(BASEADDR+2)/16'Read Port C Hi To set outputs high (1) at Port B and the lower nybble of Port C: 50 OUT BASEADDR+1,&HFF'Turn on all Port B bits 60 OUT BASEADDR+2,&HF'Turn on all bits of Port C lower nybble Manual PCI-DIO-24DH 19 Enabling/Disabling I/O Buffers When using the tristate mode (Jumper in the TST position), the method to disable the I/O buffers involved writing a control word to the Control Register at Base Address +3. This control word was required to have bit D7 (the most significant bit) set. That meant that the PPI translated it as an "active mode set" and reset the output data latches to "zero" on all output ports and the output buffers were disabled. However, if the buffers are to be enabled at a later time, the output latches will be in a "zero" state. For example, if all the outputs were 1's, they will now be 0's and the output buffers will be disabled. This problem can be resolved as follows. Two computer I/O bus addresses are available that permit you to enable or disable the I/O buffers at will, without programming the PPI mode. Buffers are enabled/disabled at Base Address + C. To enable the buffers and to set outputs to the desired state, you can write to Base + C with bit D7 low. If you wish to subsequently disable the buffers, you can write to Base + C with bit D7 high. In this way you can enable/disable the output buffers without programming the PPI mode. Note When writing a command byte to the card while the TST jumper is installed, the PPI output buffers are disabled. Thus, when you desire to to change the mode, you must first set the new mode and then enable the buffers. Enabling the buffers can be done at either Base Address +3 or Base Address +A. Interrupts The card has three sources of interrupts: 1. A Digital I/O signal on Pin 9 for the H version (50 pin), or Pin 7 for the D version (37 pin). The Digital I/O interrupt is Port C bit 3 and is enabled by installing jumpers IRQD and INT. Port C bit 3, if set for an output, can be toggled under program control to generate an interrupt. 2. An External TTL input signal on Pin 22 for the H version only. This interrupt is enabled by installing jumpers IRQD and EXT. The H version of the card also has an active-low input to disable interrupts on J1 pin 20. 3. An onboard Timer output signal from the first 82C54 output 2 (S01, S02, and S03 versions only). The Timer interrupt is enabled by installing jumpers IRQT and INT. This feature allows a “clock tick interrupt”. All interrupts are triggered on the rising edge of the signal source. All interrupts are enabled through software by writing any value to Base+E, and disabled through software by writing any value to Base+D. All interrupts are cleared by writing any value to Base+F. Refer to Chapter 3 for hardware enabling and disabling of interrupts. Refer to Table 6-1 for more on software control. Manual PCI-DIO-24DH 20 Chapter 7: 8254 Counter/Timer These cards have the option of one, two, or three 82C54 counter(s) that each include three 16-bit counter/timers factory configured in an optimal module for use as event counters, frequency output, pulse width, and frequency measurement (See Block Diagram). Each counter can be programmed to any count as low as 1 or 2, and up to 65,535, depending on the mode chosen. For those interested in more detailed information, a full description can be found in the Intel (or equivalent manufacturer's) data sheet. Operational Modes The 8254 modes of operation are described in the following paragraphs to familiarize you with the versatility and power of this device. For those interested in more detailed information, a full description of the 8254 programmable interval timer can be found in the Intel (or equivalent manufacturers') data sheets. The following conventions apply for use in describing operation of the 8254 : Clock: A positive pulse into the counter's clock input Trigger: A rising edge input to the counter's gate input Counter Loading: Programming a binary count into the counter Mode 0: Pulse on Terminal Count After the counter is loaded, the output is set low and will remain low until the counter decrements to zero. The output then goes high and remains high until a new count is loaded into the counter. A trigger enables the counter to start decrementing. Mode 1: Retriggerable One-Shot The output goes low on the clock pulse following a trigger to begin the one-shot pulse and goes high when the counter reaches zero. Additional triggers result in reloading the count and starting the cycle over. If a trigger occurs before the counter decrements to zero, a new count is loaded. This forms a retriggerable one-shot. In mode 1, a low output pulse is provided with a period equal to the counter count- down time. Mode 2: Rate Generator This mode provides a divide-by-N capability where N is the count loaded into the counter. When triggered, the counter output goes low for one clock period after N counts, reloads the initial count, and the cycle starts over. This mode is periodic, the same sequence is repeated indefinitely until the gate input is brought low. This mode also works well as an alternative to mode 0 for event counting. Mode 3: Square Wave Generator This mode operates like mode 2. The output is high for half of the count and low for the other half. If the count is even, then the output is a symmetrical square wave. If the count is odd, then the output is high for (N+1)/2 counts and low for (N-1)/2 counts. Periodic triggering or frequency synthesis are two possible applications for this mode. Note that in this mode, to achieve the square wave, the counter decrements by two for the total loaded count, then reloads and decrements by two for the second part of the wave form. Mode 4: Software Triggered Strobe This mode sets the output high and, when the count is loaded, the counter begins to count down. When the counter reaches zero, the output will go low for one input period. The counter must be reloaded to repeat the cycle. A low gate input will inhibit the counter. Mode 5: Hardware Triggered Strobe In this mode, the counter will start counting after the rising edge of the trigger input and will go low for one clock period when the terminal count is reached. The counter is retriggerable. The output will not go low until the full count after the rising edge of the trigger. Manual PCI-DIO-24DH 21 Counter/Timer Registers Base + 10 Write/Read: Counter#A0 When writing, this register is used to load a count value into the counter. The transfer is either a single or double byte transfer, depending on the control byte written to the counter control register at BASE ADDRESS +13. If a double byte transfer is used, then the least- significant byte of the 16 bit value is written first, followed by the most significant byte. When reading, the current count of the counter is read. The type of transfer is also set by the control byte. Base + 11 Write/Read: Counter #A1 See description for Base + 10 Write/Read. Base + 12 Write/Read: Counter #A2 See description for Base + 10 Write/Read. Base + 13 Write: Counter Control Register The control byte specifies the counter to be programmed, the counter mode, the type of read/write operation, and the modulus. The control byte format is as follows: These cards contain a type 8254 programmable counter/timer that allows you to implement such functions as a Real Time Clock, Event Counter, Digital One-Shot, Programmable Rate Generator, Binary Rate Multiplier, Complex Wave Generator and/or a Motor Controller. The 8254 consists of three, 16-bit, presettable, down counters. Each counter can be programmed to any count between 1 or 2 and 65,535 in binary format depending on the mode chosen. Manual PCI-DIO-24DH 22 Programming the 8254 The counters are programmed by writing a control byte into the counter control register. Refer to the previous register map for the base addresses of the counters and the counter control register. The control byte specifies the counter to be programmed, the counter mode, the type of read/write operation, and the modulus. The control byte format is as follows: B7 B6 B5 B4 B3 B2 B1 B0 SC1 SC0 RW1 RW0 M2 M1 M0 BCD SC0-SC1: These bits select the counter that the control byte is destined for. SC1 SC0 Function 0 0 Program Counter #0 0 1 Program Counter #1 1 0 Program Counter #2 1 1 Read/Write Cmd.* * See section on Reading and Loading the Counters. RW0-RW1: These bits select the read/write mode of the selected counter. RW1 RW0 Counter Read/Write Function 0 0 Counter Latch Command 0 1 Read/Write LS Byte 1 0 Read/Write MS Byte 1 1 Read/Write LS Byte, then MS Byte M0-M2: These bits set the operational mode of the selected counter. Mode M2 M1 M0 0 0 0 0 1 0 0 1 2 X 1 0 3 X 1 1 4 1 0 0 5 1 0 1 BCD: Set the selected counter to count in binary (BCD = 0) or BCD (BCD = 1). Manual PCI-DIO-24DH 23 Reading and Loading the Counters If you attempt to read the counters on the fly when there is a high input frequency, you will most likely get erroneous data. This is partly caused by carries rippling through the counter during the read operation. Also, the low and high bytes are read sequentially rather than simultaneously and, thus, it is possible that carries will be propagated from the low to the high byte during the read cycle. To circumvent these problems, you can perform a counter-latch operation in advance of the read cycle. To do this, load the RW1 and RW2 bits with zeroes. This instantly latches the count of the selected counter (selected via the SC1 and SC0 bits) in a 16-bit hold register. (An alternative method of latching counter(s) that has an additional advantage of operating simultaneously on several counters is through a readback command to be discussed later.) A subsequent read operation on the selected counter returns the held value. Latching is the best way to read a counter on the fly without disturbing the counting process. You can only rely on directly read counter data if the counting process is suspended while reading by bringing the gate low. For each counter you must specify in advance the type of read or write operation that you intend to perform. You have a choice of loading/reading (a) the high byte of the count, or (b) the low byte of the count, or (c) the low byte followed by the high byte. This last is most generally used and is selected for each counter by setting the RW1 and RW0 bits to ones. Subsequent read/load operations must be performed in pairs in this sequence or the sequencing flip-flop in the 8254 chip will get out of step. The readback command byte format is: B7 B6 B5 B4 B3 B2 B1 B0 1 1 CNT STA C2 C1 C0 0 CNT: When 0, latches the counters selected by bits C0-C2. STA: When 0, returns the status byte of counters selected by C0-C2. C0, C1, C2: When high, select a particular counter for readback. C0 selects Counter 0, C1 selects Counter 1, and C2 selects Counter 2. You can perform two types of operations with the readback command. When CNT=0, the counters selected by C2 through C0 are latched simultaneously. When STA=0, the counter status byte is read when the counter I/O location is accessed. The counter status byte provides information about the current output state of the selected counter and its configuration. The status byte returned if STA=0 is: B7 B6 B5 B4 B3 B2 B1 B0 OUT NC RW1 RW2 M2 M1 M0 BCD OUT: Current state of counter output pin. NC: Null count. This indicates when the last count loaded into the counter register has been loaded into the actual counter. The exact time of load depends on the configuration selected. Until the count is loaded into the counter, it cannot be read. RW1, RW0: Read/Write command. M2, M1, M0: Counter mode. BCD: BCD = 0 is binary mode, otherwise counter is in BCD mode. If both STA and CNT bits in the readback command byte are set low and the RW1 and RW0 bits have both been previously set high in the counter control register (thus selecting two-byte reads), then reading a selected counter address location will yield: Manual PCI-DIO-24DH 24 1st Read: Status byte 2nd Read: Low byte of latched data 3rd Read: High byte of latched data After any latching operation on a counter, the contents of its hold register must be read before any subsequent latches of that counter will have any effect. If a status latch command is issued before the hold register is read, then the first read will read the status, not the latched value. 8254 Driver A simple driver is provided to perform basic counter/timer operations on this card. Source code for the driver and a sample program showing how to use the functions are located in the DOS\CSAMPLES directory. The following functions are provided: Frequency Measure The Frequency Measure function of the 8254 Counter Driver has the ability to measure an unknown frequency from 1KHz to 2MHz. This function requires as input the Base Address of the card. The unknown frequency is applied to the CLOCK IN pin of the card. The function will return the frequency as a long integer in Hz. long frequency_measure(unsigned BaseAddress); Event Counter The Event Counter function has the ability to trace the number of events that have occurred. This function requires the Base Address and an additional parameter that identifies which features should be implemented on this call to the function. Each feature can be identified by its unique integer value. Multiple features can be run in a single call to the function by ORing the respective integer values together. Features will be executed in increasing integer order. The CLOCK IN pin of the card is the point of application for the incoming events. (Note: This function is limited by the input speed of the 8254 counter, and slow signals are preferred. Further only 65,535 events are possible without a RESET.) The function returns the number of events (based on priority) or 0 for those features that do not specify a return value. Features: INITIALIZE = 1; initialize the counter START = 2; begin counting SINCESTART = 4; return the number of events since the start SINCELAST = 8; return the number of events since last check STOP = 16; stop counting events RESET = 32; reset number of events to 0 unsigned event_counter(unsigned BaseAddress, int feature); Generate Frequency The Generate Frequency function will generate a square wave (0 to +5V) with the desired frequency. The Base Address of the card as well as the frequency are required as input to the function. The counter can generate a frequency with a range of 1Hz to 250KHz. The square wave can be read on the CLOCK OUT pin of the card. void generatefrequency(unsigned BaseAddress, unsigned long frequency); Manual PCI-DIO-24DH 25 Pulse Width The Pulse Width function will measure the width of an applied event from its rise to its fall (effectively one half the period). The Base Address of the card is required as input to the function. The signal should be applied to the CLOCK IN pin of the card. Software latency will be affected by the operating system and will set a limit on the precision of the measurement. unsigned pulse_width(unsigned BaseAddress); Manual PCI-DIO-24DH 26 Chapter 8: Connector Pin Assignments The H card has a 50-pin connector provided on the back plate of these cards for I/O connections. The mating connector is an AMP type 1-746285-0 or equivalent. Connector pin assignments are listed below. Assignment Pin Assignment Pin PC7 1 Counter A0 Freq In 2 PC6 3 Ctr A1 P.W.I. (Gate) 4 Port C Hi PC5 5 Counter A2 Freq Out 6 PC4 7 Counter B0 Freq in 8 PC3 9 Ctr B1 P.W.I. (Gate) 10 PC2 11 Counter B2 Freq Out 12 Port C Lo PC1 13 Counter C0 Freq In 14 PC0 15 Ctr C1 P.W.I. (Gate) 16 PB7 17 Ctr C2 Freq Out 18 PB6 19 Digital Int Disable 20 PB5 21 External Int Source 22 PB4 23 24 Port B PB3 25 26 PB2 27 28 PB1 29 30 PB0 31 32 PA7 33 34 PA6 35 Even pins 24-50 36 are all Ground PA5 37 38 PA4 39 40 Port A PA3 41 42 PA2 43 44 PA1 45 46 PA0 47 48 Fused +5 VDC 49 50 Table 8-1: 50-Pin Connector Pin Assignments Manual PCI-DIO-24DH 27 The D card has a 37-pin D-sub connector provided on the back plate of these cards for I/O connections. If all three counters are present, pin 20 is counter C2's frequency output. Otherwise, pin 20 is fused +5V power. Assignment Pin Assignment Pin Ground 1 Digital IRQ Disable 2 C2 Freq Out / Fused +5V 20 Port C 7 Hi 3 Ground 21 Port C 6 Hi 4 Port B 7 22 Port C 5 Hi 5 Port B 6 23 Port C 4 Hi 6 Port B 5 24 Port C 3 Lo 7 Port B 4 25 Port C 2 Lo 8 Port B 3 26 Port C 1 Lo 9 Port B 2 27 Port C 0 Lo 10 Port B 1 28 Counter A0 Freq In 11 Port B 0 29 Ctr A1 P.W.I. (Gate) 12 Port A 7 30 Counter A2 Freq Out 13 Port A 6 31 Counter B0 Freq in 14 Port A 5 32 Ctr B1 P.W.I. (Gate) 15 Port A 4 33 Counter B2 Freq Out 16 Port A 3 34 Counter C0 Freq In 17 Port A 2 35 Ctr C1 P.W.I. (Gate) 18 Port A 1 36 Ground 19 Port A 0 37 Table 8-2: 37-Pin D-Sub Connector Pin Assignments Manual PCI-DIO-24DH 28 Customer Comments If you experience any problems with this manual or just want to give us some feedback, please email us at: tech@portwell.com. Please detail any errors you find and include your mailing address so that we can send you any manual updates. Manual PCI-DIO-24DH 29

Frequently asked questions

What makes Portwell Boards unique?

What kind of warranty will the PCI-DIO-24D have?

Which carriers does Portwell Boards work with?

Will Portwell Boards sell to me even though I live outside the USA?

I have a preferred payment method. Will Portwell Boards accept it?

Why buy from GID?

Quality

We are industry veterans who take pride in our work

Protection

Avoid the dangers of risky trading in the gray market

Access

Our network of suppliers is ready and at your disposal

Savings

Maintain legacy systems to prevent costly downtime

Speed

Time is of the essence, and we are respectful of yours

Related Products

Half-size Low-Profile PCI bus compatible card that provides isolated digital input and output interf...

Parallel digital input/output cards designed for use in PCI-Bus computers. The same printed circuit ...

24-bit parallel, digital input/output cards designed for use in PCI-Bus computers. PCI-DIO24H are vi...

24-bit parallel digital input/output cards designed for use in PCI-Bus computers. The card is 6.9 in...

48-bit parallel digital input/output cards designed for use in PCI-Bus computers. The card is 6.9 in...

Manufacturers

Manufacturers

What they say about us

FANTASTIC RESOURCE

One of our top priorities is maintaining our business with precision, and we are constantly looking for affiliates that can help us achieve our goal. With the aid of GID Industrial, our obsolete product management has never been more efficient. They have been a great resource to our company, and have quickly become a go-to supplier on our list!

Bucher Emhart Glass

EXCELLENT SERVICE

With our strict fundamentals and high expectations, we were surprised when we came across GID Industrial and their competitive pricing. When we approached them with our issue, they were incredibly confident in being able to provide us with a seamless solution at the best price for us. GID Industrial quickly understood our needs and provided us with excellent service, as well as fully tested product to ensure what we received would be the right fit for our company.

Fuji

HARD TO FIND A BETTER PROVIDER

Our company provides services to aid in the manufacture of technological products, such as semiconductors and flat panel displays, and often searching for distributors of obsolete product we require can waste time and money. Finding GID Industrial proved to be a great asset to our company, with cost effective solutions and superior knowledge on all of their materials, it’d be hard to find a better provider of obsolete or hard to find products.

Applied Materials

CONSISTENTLY DELIVERS QUALITY SOLUTIONS

Over the years, the equipment used in our company becomes discontinued, but they’re still of great use to us and our customers. Once these products are no longer available through the manufacturer, finding a reliable, quick supplier is a necessity, and luckily for us, GID Industrial has provided the most trustworthy, quality solutions to our obsolete component needs.

Nidec Vamco

TERRIFIC RESOURCE

This company has been a terrific help to us (I work for Trican Well Service) in sourcing the Micron Ram Memory we needed for our Siemens computers. Great service! And great pricing! I know when the product is shipping and when it will arrive, all the way through the ordering process.

Trican Well Service

GO TO SOURCE

When I can't find an obsolete part, I first call GID and they'll come up with my parts every time. Great customer service and follow up as well. Scott emails me from time to time to touch base and see if we're having trouble finding something.....which is often with our 25 yr old equipment.

ConAgra Foods